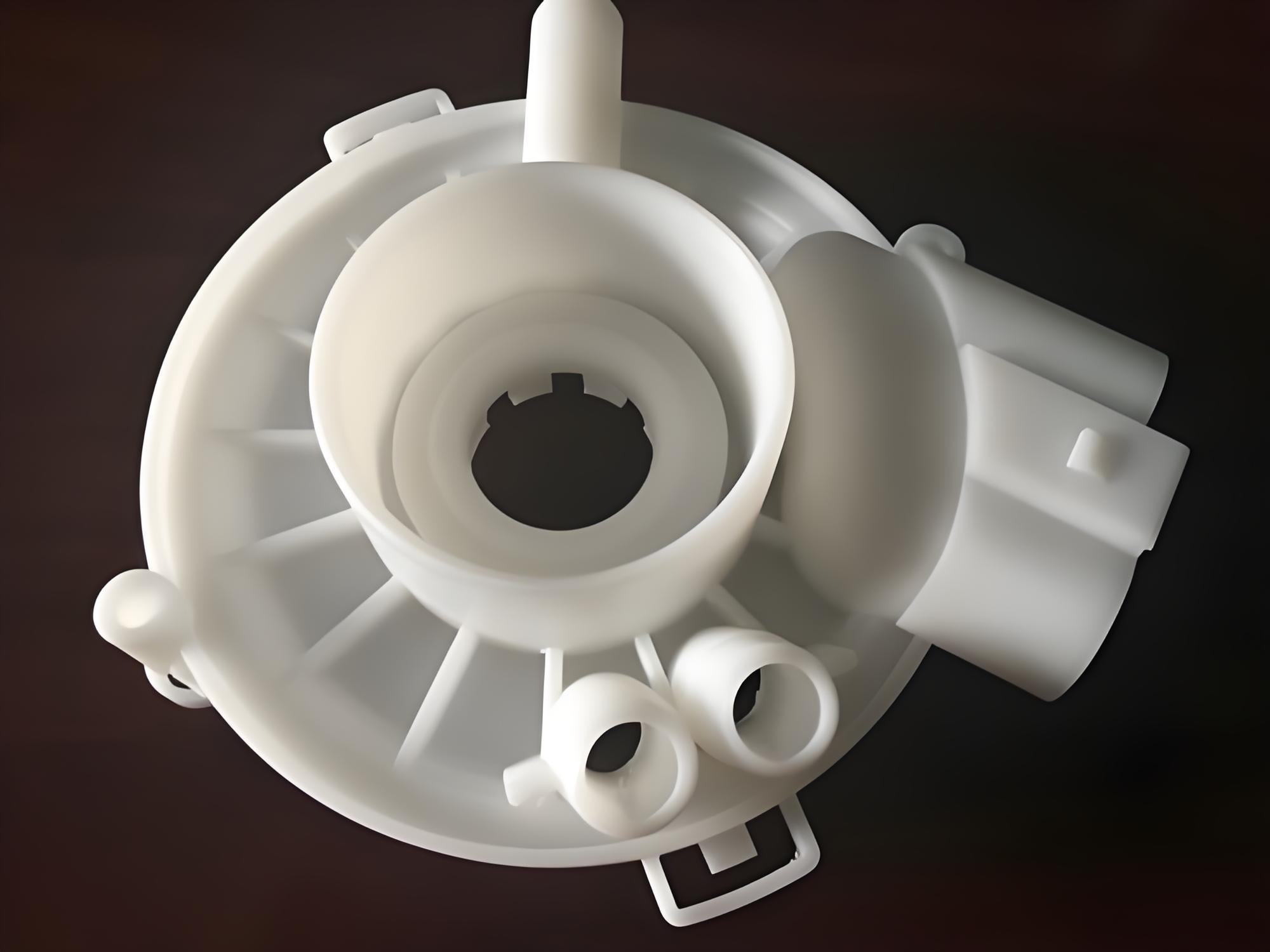

3D printing is an additive manufacturing process where a three-dimensional object is crafted layer by layer, following a digital model. No longer confined to prototyping or simple designs, modern 3D printers can produce complex geometries, employ a range of materials from plastics to metals, and are utilized in industries ranging from fashion to aerospace. At Linkwork, we specialize in providing high-quality plastic 3D printing solutions that meet diverse design and manufacturing needs.

Understanding the Basics of Plastic 3D Printing

When designing parts for plastic 3D printing, it’s essential to understand the unique characteristics of the materials and the printing process. Different types of plastics, such as ABS, PLA, and Nylon, have varying properties that affect their suitability for different applications. For instance, ABS is known for its strength and durability, while PLA is praised for its ease of use and biodegradability.

Key Considerations for Designing Parts

1. Design for Additive Manufacturing

Unlike traditional manufacturing methods that often require complex tooling, 3D printing allows for greater design freedom. When designing parts, consider the following:

- Complex Geometries: Take advantage of the ability to create intricate shapes that would be difficult or impossible to achieve with conventional methods.

- Weight Reduction: Use lattice structures or hollow designs to minimize weight without sacrificing strength.

2. Material Selection

Choosing the right plastic material is crucial for achieving the desired performance characteristics. Factors to consider include:

- Mechanical Properties: Assess the strength, flexibility, and impact resistance required for your application.

- Thermal Stability: Ensure that the selected material can withstand the operating temperatures it will encounter.

3. Layer Orientation

The orientation of the part during printing can significantly affect its mechanical properties. Parts printed vertically may have different strength characteristics compared to those printed horizontally. Consider how the part will be used and orient it accordingly to optimize strength and minimize warping.

4. Support Structures

Depending on the complexity of your design, you may need to incorporate support structures to prevent sagging or deformation during printing. Design these supports in a way that they can be easily removed post-printing without damaging the part.

5. Tolerance and Fit

When designing parts that will fit together or interact with other components, it’s essential to account for tolerances. Ensure that there is enough clearance between moving parts to allow for easy assembly and operation.

Prototyping and Iteration

One of the significant advantages of 3D printing is rapid prototyping. Once you have a design, you can quickly produce a prototype to test its functionality and fit. This iterative process allows you to make adjustments based on real-world feedback before finalizing your design.

Conclusion

Designing parts for plastic 3D printing requires careful consideration of various factors, from material selection to design for additive manufacturing principles. At Linkwork, we are committed to helping you navigate these considerations to create high-quality, functional parts that meet your specific needs. Whether you are looking to prototype a new product or produce components for an existing application, our expertise in plastic 3D printing can help bring your ideas to life efficiently and effectively. If you're ready to explore our offerings or need assistance with your designs, don't hesitate to reach out!